Forward to the Roots

Witchburn is a new distillery in the time-honored Campbeltown whisky region! True to the motto „Forward to the Roots“ we will produce a Scotch Single Malt Whisky with methods from many decades ago. In doing so, we will rely on state-of-the-art engineering to achieve this in a sustainable, carbon-neutral manner and without the use of fossil fuels, making us one of the most modern distilleries in the country.

With Witchburn, we want to do our part to bring the glory days back to Scotland’s former whisky capital Campbeltown, when there were more than 30 active distilleries.

Work in progress

The Halls Fill with Steel and Copper

Over the past weeks, more and more deliveries have arrived at Machrihanish – pumps, condensers, tanks, miles of pipework, and countless smaller components.

Bit by bit, the halls of the old building have filled with stainless steel, copper, and the quiet energy of progress. With all major equipment now on site, the real work begins: installation, connection, testing – bringing every part together to form a living, working distillery. Witchburn is ready for the next chapter.

A Seven-Ton Arrival

After weeks of preparation, one of the most impressive deliveries reached Machrihanish – the electric steam boiler.

It took cranes, careful rigging, and hours of precision work to guide the massive unit into the old building. Even a section of the wall had to be opened to make room for its size.

Piece by piece, the equipment was moved inside until everything finally fit. A challenging day – but another major step towards bringing Witchburn to life.

The First Giants Take Their Place

First Equipment Arrives

After months of engineering and preparation, all major equipment has now arrived at Machrihanish – a milestone that marks the transition from planning to reality.

The mash tun, washbacks, and numerous stainless-steel tanks were delivered over several days and carefully unloaded with cranes, one by one.

What had existed only in drawings and 3D models is now here, ready to be installed in the heart of the old building.

With every delivery, Witchburn is taking clearer shape – step by step, from empty halls to a working distillery in the making.

Construction Begins

Once the final designs were approved and the first equipment went into production, work on site began.

The existing buildings at Machrihanish are now being carefully stripped back, cleaned, and prepared for their new purpose. What had once been part of a US Navy SEAL training facility is being transformed – step by step – into the home of a modern, sustainable distillery.

The structure isn’t listed or protected, but that doesn’t make things easier. Behind more than one wall, we keep finding a few surprises – reminders of the site’s long and sometimes unexpected history. Every section is being renewed or reinforced to meet today’s standards while keeping the building’s solid, authentic character intact.

It’s a careful balance between restoration and renewal – shaping the space that will soon bring Witchburn to life.

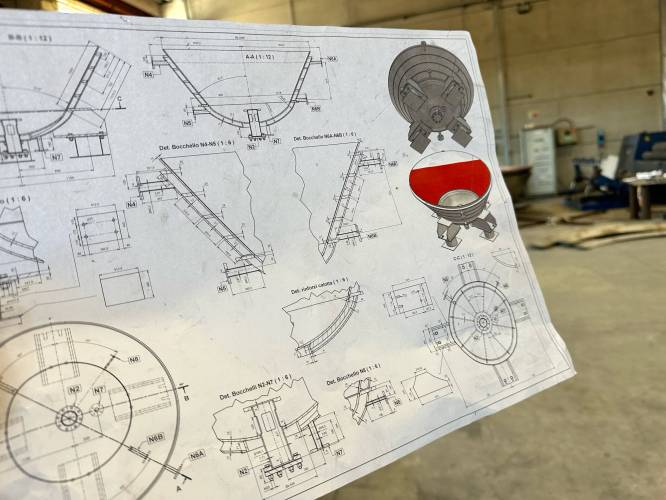

Equipment Production Begins

After months of detailed planning and engineering, the first parts of Witchburn began to take shape.

Although the distillery itself is being built within existing structures in Campbeltown, much of the equipment is being manufactured across Europe – in specialised workshops in Scotland, Italy, the Czech Republic, Germany, and Switzerland.

Our stills, condensers, tanks, and pipework are all crafted to custom specifications, designed to handle the high temperatures and energy systems that make Witchburn unique. Each element is produced with the same goal: to combine traditional whisky-making principles with modern precision and sustainability.

Bit by bit, the components that will soon fill the halls of the old building are taking form – ready to be assembled into a working distillery unlike any other.

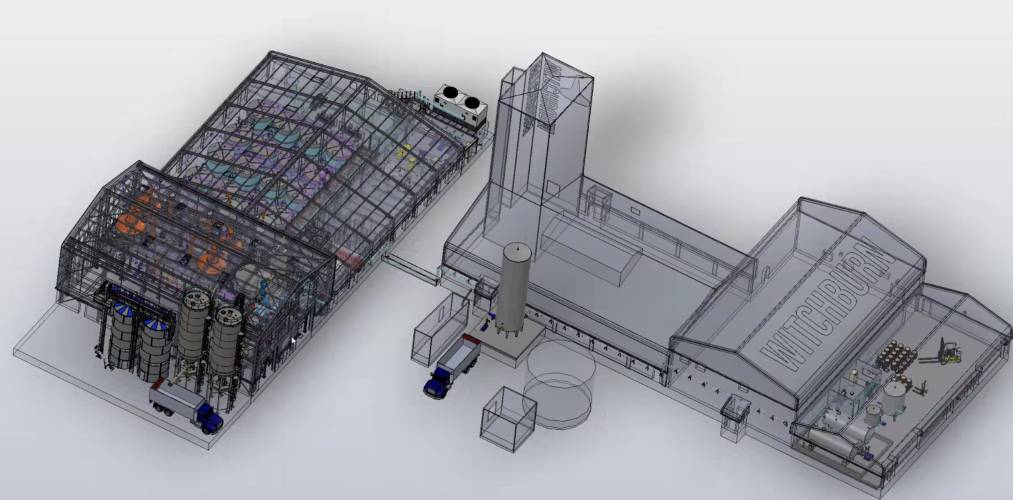

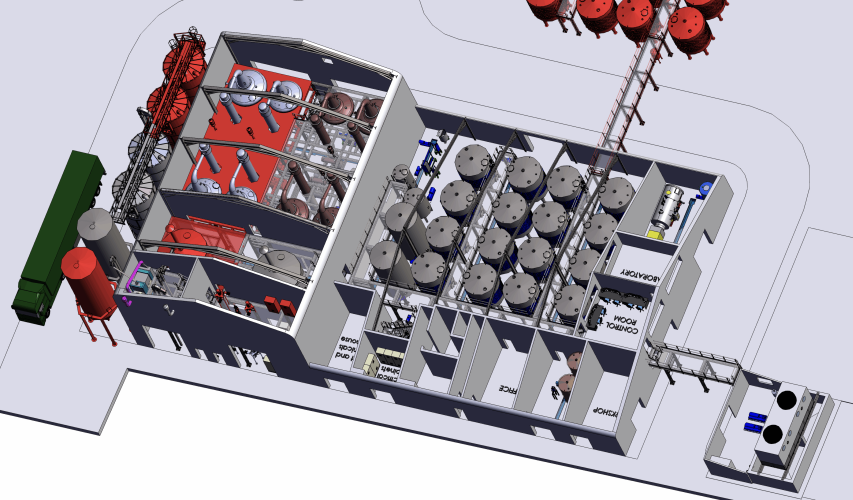

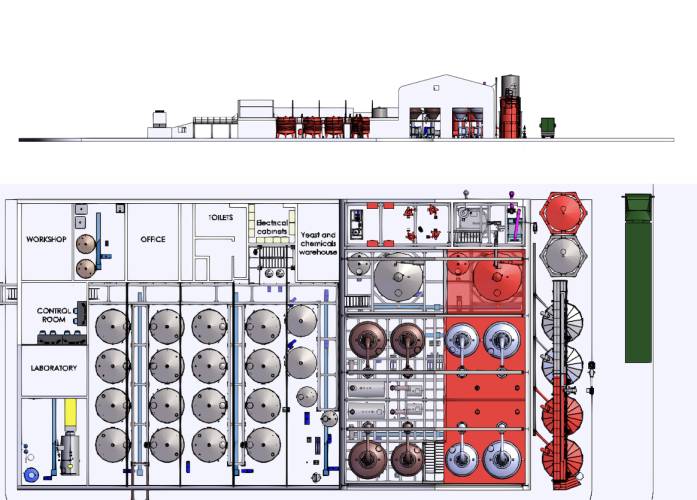

Engineering Completed

Once the plans were approved, the real precision work began. Every pipe, pump, and valve had to be designed to match our specific production philosophy – from the high-temperature distillation setup to the energy-efficient heat-recovery system.

Together with our engineering partners, we translated Witchburn’s vision into technical reality: a distillery capable of producing traditional, high-intensity spirit in a completely sustainable way.

When the final engineering documents were signed off, we knew the foundation was ready – not just for construction, but for a new chapter in Campbeltown’s whisky history!

Planning & Permission

Transforming a historic building into a modern distillery is never simple – especially when it sits just a few hundred metres from the Atlantic. Every wall, every pipe, every plan had to meet the highest standards for safety, sustainability, and heritage protection.

Working closely with engineers, architects, and the local authorities in Campbeltown, we shaped a concept that respects the character of the old structure while making room for state-of-the-art whisky production.

After months of detailed design and environmental review, planning permission was granted – a major milestone that turned Witchburn from vision into reality!

A Bold Idea ... and the Right Building

It all began with a bold idea – to bring whisky making back to Campbeltown, the cradle of Scotland’s whisky heritage. Only a few places embody craftsmanship, character, and tradition quite like this town.

After months of research, we found the perfect fit: a historic site near Machrihanish, where old military buildings meet the winds from the Atlantic. Enough space to give our vision room to grow – with an on-site warehouse, space for sixteen massive washbacks, and ceilings high enough to host stills and condensers worthy of the name Witchburn.

The main building itself has stood firm for decades, defying the fierce winds and weather of the coast – solid, enduring, and ready to be reborn as the heart of a new distillery!